Sichuan Porous Technology Co., Ltd.

Your Expert in Metal Porous Material Solutions

As a National High-Tech Enterprise specializing in R&D, manufacturing, and global distribution of

titanium/nickel-based porous materials, we operate a 5,000㎡ smart

manufacturing base in Deyang City, Sichuan Province. Equipped with

end-to-end production capabilities, we deliver cutting-edge porous

metal solutions to clients across 30+ countries.

We are “High Quality | Customized | Large Capacity Source Direct, Cost

Effective Choice”, we are one-stop self-produced and highly trusted, and in the near

future, we will make our products to be loved and chosen by more

people and countries.

Core Strengths ✅ Industrial-Scale Production: 300+ tons/year of HDH titanium & titanium alloy powders 100,000 sq.m/year of gas diffusion layers (TPF/NPF) for hydrogen

energy applications ✅ Tech-Driven Innovation: R&D leadership by Central South University’s materials science

experts 16 proprietary patents in powder metallurgy and gradient porous

material technologies ✅ Global Compliance: ISO 9001-certified quality management system Rigorous process control from raw materials to finished products

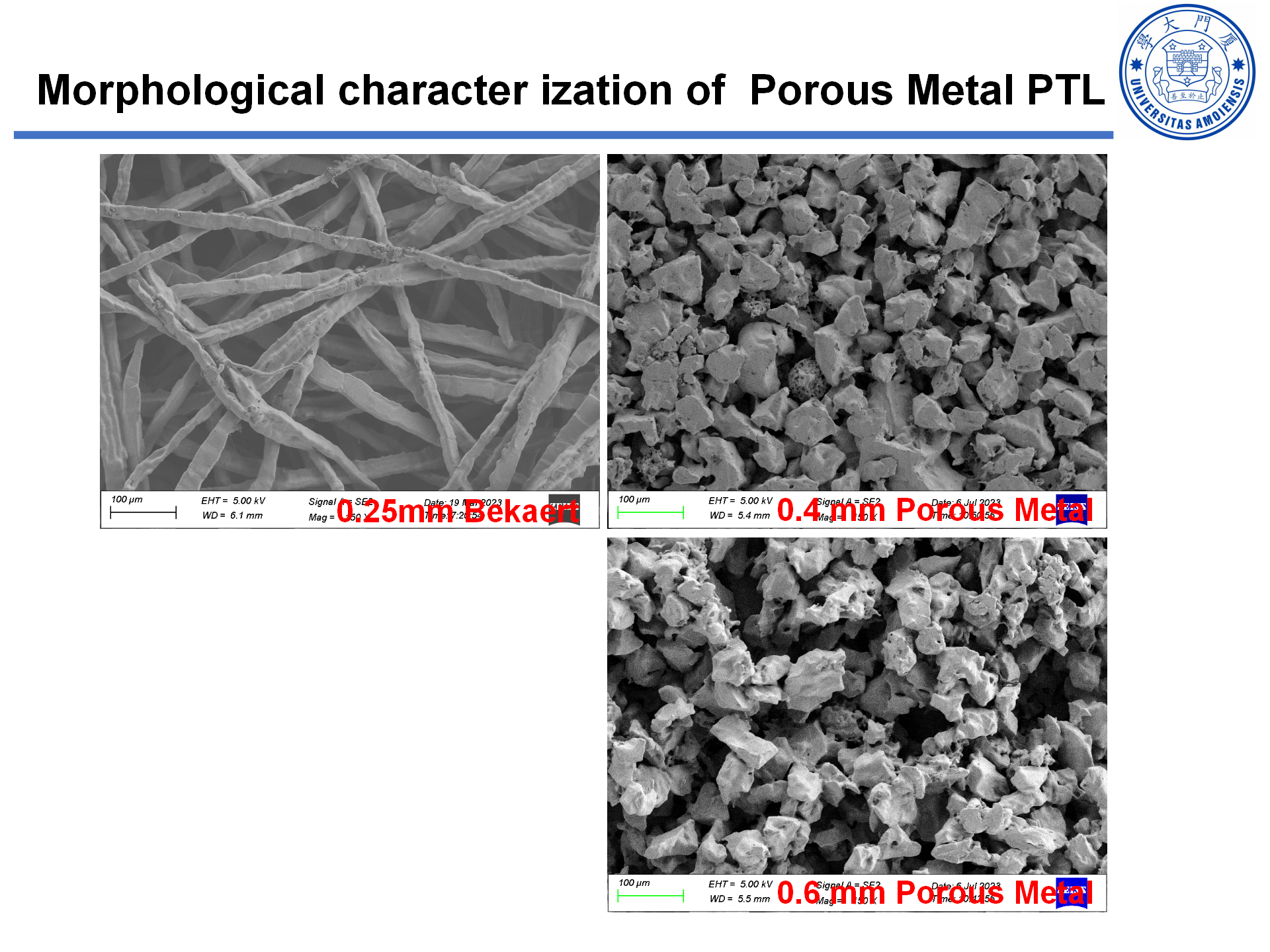

Flagship Products ✓ Titanium & Titanium Alloy Powders (HDH Method) ✓ Titanium-Based

Gas Diffusion Layers (TPF) ✓ Nickel-Based Gas Diffusion Layers

(NPF) ✓ Customized Porous Metal Filters

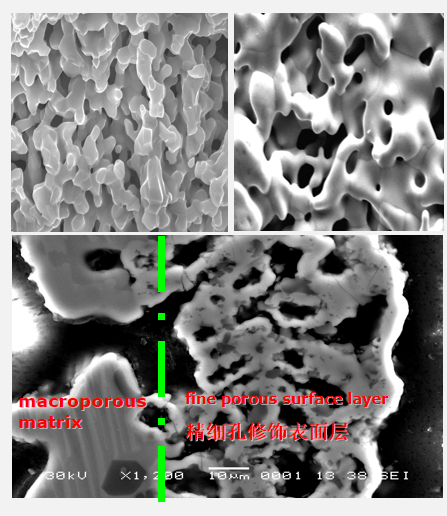

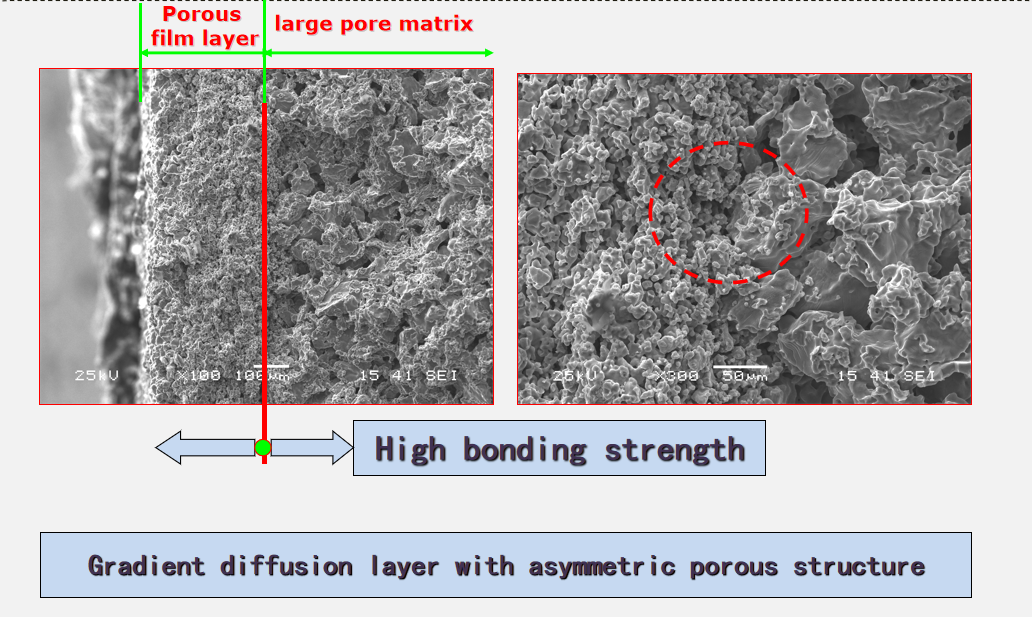

Hydrogen Energy Expertise Our gas diffusion layers (GDLs) are globally validated for PEM/AEM

water electrolysis systems, featuring: ✓60-85% adjustable porosity ✓Superior conductivity & corrosion resistance ✓High consistency for mass production

Why Partner With Us? ✓Vertical Integration: Full control over R&D, production, and

quality assurance ✓Application Focus: Proven performance in 3D printing, MIM

injection molding, and green hydrogen equipment ✓Custom Solutions: Tailored porosity, thickness, and material

configurations

Visit Our Smart Factory Explore how our advanced powder metallurgy processes and automated

production lines ensure cost-efficient, high-performance solutions for your industry.